We have been in Iron & Steel industry since 1960's

- Customised Alloy Steel Solutions

- Casted With Excellence

Our hard work & quality brought laurels, rest is history. The strong values of a family-run enterprise, backed by industry professionals gave direction to the foundation Mr. Abhinav Joshi (third generation) the young enterprising son of Mr. Naresh Joshi, innovated new dimensions and horizons to explore a new clientele in Forging and Casting Steel sectors.

We have an ultramodern manufacturing facility spreading over an area of 1,20,000 sq. feet, located at Mandi Gobindgarh (Punjab) North-West of India. We have an installed capacity for producing over 6000 MT of liquid metal per annum.

ANJ METALS RECYCLING PVT. LTD.

is an ISO 9001:2015 certified company.

This prestigious certification is a testament to our commitment to quality and excellence in all aspects of our operations. It reflects our dedication to providing top-notch recycling services while adhering to the highest industry standards.

Industries We Serve

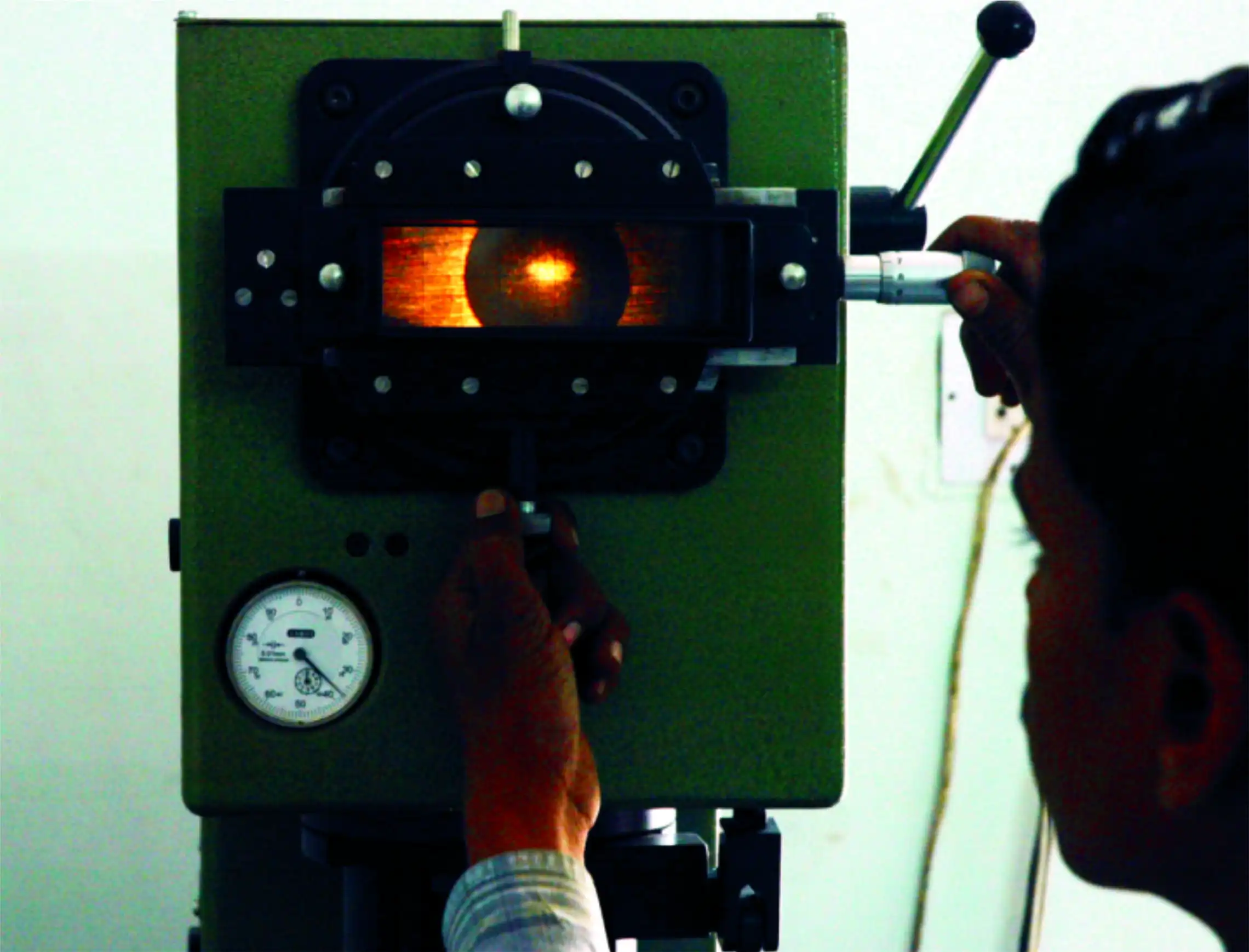

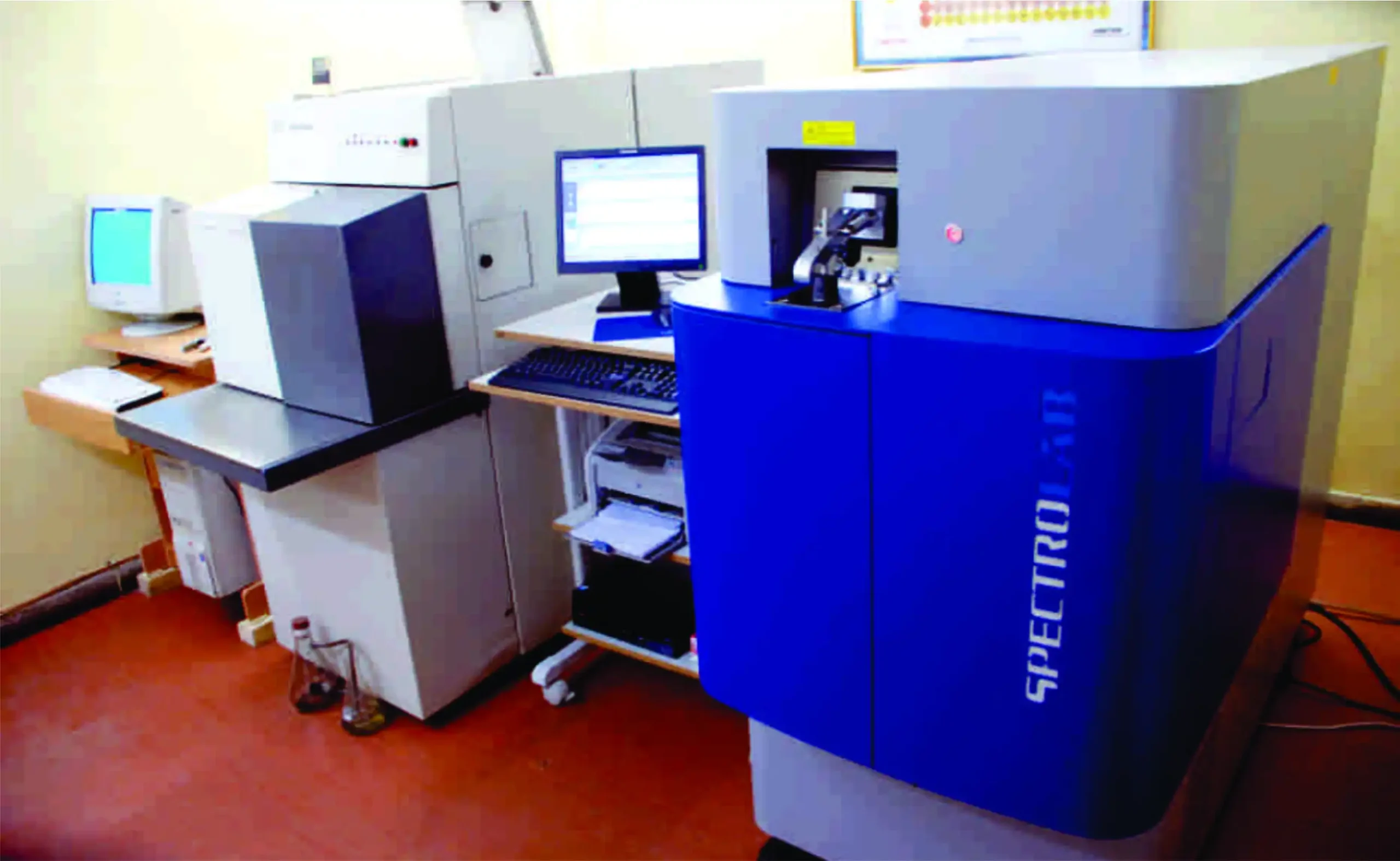

Infrastructure & Quality Control

we take immense pride in our industry-leading manufacturing capabilities, specializing in the production of the highest quality castings and alloy steel forgings. Our state-of-the-art infrastructure is designed to meet the most demanding requirements, enabling us to deliver exceptional products that exceed industry standards. With cutting-edge technology and modern machinery, we ensure precision and accuracy at every step of the manufacturing process. Our skilled technicians and engineers work tirelessly to create castings and alloy steel forgings that are second to none.

Quality control is at the heart of everything we do. We employ stringent measures to guarantee the durability, strength, and reliability of our products. Each casting and forging undergoes rigorous testing and inspection, adhering to international quality standards.

By investing in advanced testing equipment and employing a team of experienced quality control professionals, we leave no stone unturned in delivering excellence to our valued customers.

Our commitment to quality extends beyond the manufacturing process. We continuously strive to improve our operations, embracing innovative techniques and staying up-to-date with the latest industry advancements. This dedication enables us to consistently provide castings and alloy steel forgings that surpass expectations.

- Spectomax Germany 26 Channels Spectrometer

- Cutting & Polishing Machine

- Metallurgical Microscope

- Micro Structure Analysis

- Digital Hardness Tester

- Universal Testing Machine

- Ultrasonic Testing Machine

- Dye Penitrant Testing (D.P)

- Magnetic Particle Inspection (MPI)